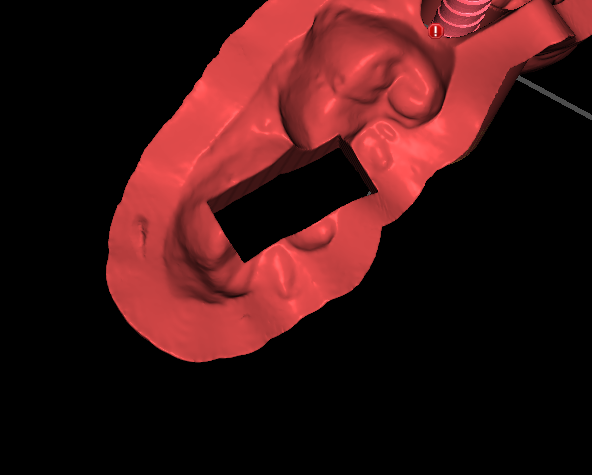

In the attached image, the rectangular cropped area on the surface is cleanly cut, and the sidewall boundary is extruded in a different direction, resulting in a visible thickness between the cropped surface and the sidewall. It looks like the sidewall is extruded along a normal or tangential direction, instead of simply following the direction of the rectangular crop.

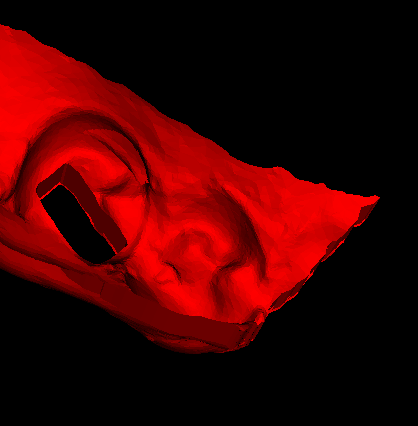

In my current surgical guide generation workflow, however, the cropped surface and sidewall are aligned in the same direction—there’s no boundary wall thickness, and the wall extends directly and perpendicularly from the cropped surface without any offset.

How can I modify my extrusion logic to replicate the result shown in the image—where a single extrusion operation produces a sidewall that deviates from the crop direction and creates a boundary wall with thickness? I’d prefer to achieve this in a single extrusion step, as using two separate extrusions creates two disconnected or overlapping layers.

Below one is the Surgical guide created by me!