Hi everyone,

I am implementing a mesh cutting feature using vtkBoxClipDataSet on arbitrary meshes.

-

Input: Arbitrary

vtkPolyDataconstructed from triangle parameters (in my current test case, the geometry happens to be a cylinder, but it could be any shape). -

Pipeline:

vtkBoxClipDataSet→vtkTriangleFilter→vtkCleanPolyData→vtkPolyDataNormals.

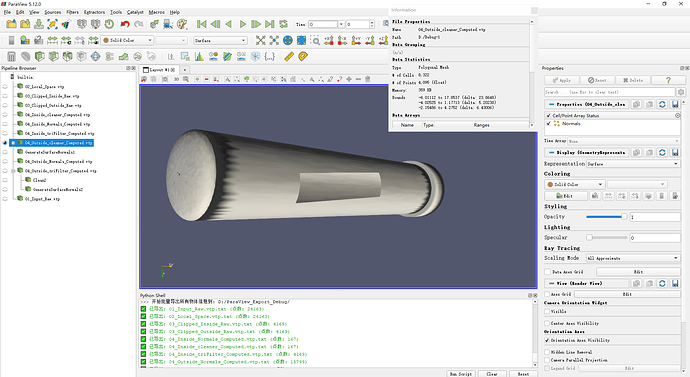

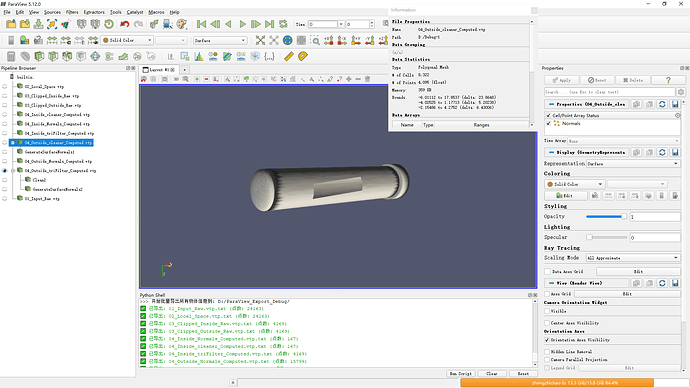

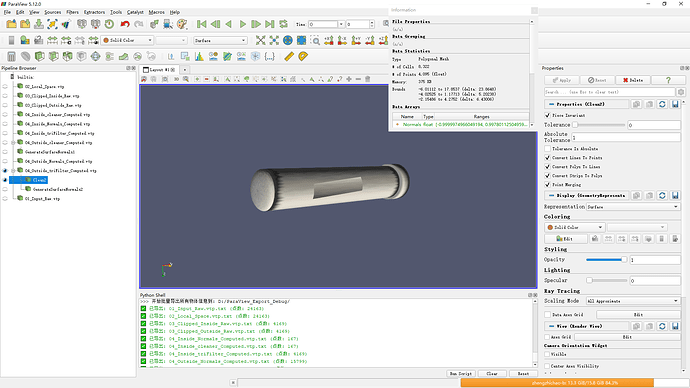

I have prototyped this workflow in ParaView, and it produces a smooth, continuous surface. However, when I implement the exact same pipeline in C++, the result looks “shattered” (hard edges everywhere), as if every triangle is detached.

My Investigation & Evidence

To isolate the issue, I exported .vtp files at every stage of my C++ pipeline and compared them with manual filters in ParaView (A/B testing).

1. Confirming “Clean” works in C++

-

File A:

04_Outside_cleaner_Computed.vtp(Exported after C++vtkCleanPolyData). -

File B:

04_Outside_triFilter_Computed.vtp(Exported after C++ Triangulation) → Manually appliedCleanfilter in ParaView. -

Observation: Both File A and File B have the exact same number of points and cells (Point count reduced from ~15k to ~4k).

-

Conclusion: This confirms that my C++

vtkCleanPolyData(usingSetToleranceIsAbsolute(true)with1e-3) is correctly merging vertices. The topology is closed at this stage.

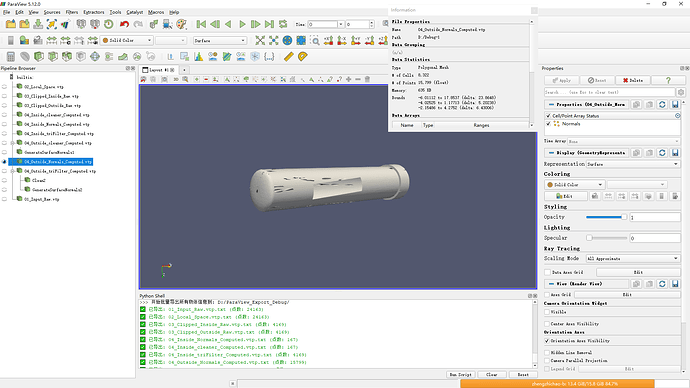

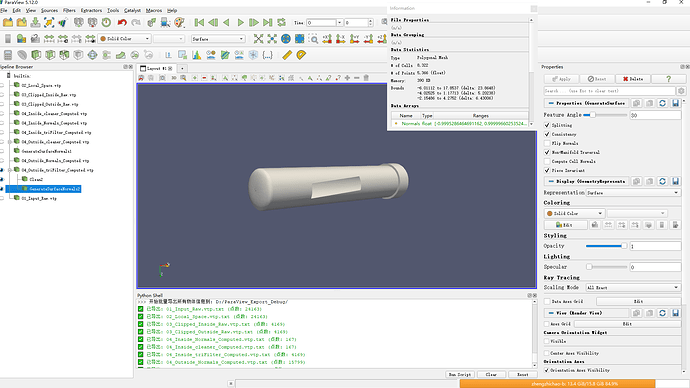

2. The discrepancy happens at the “Normals” step I compared three scenarios for normal generation:

-

Scenario 1 (Pure C++ Pipeline): Automated code execution.

- Result: Point count jumps back to ~15k. The mesh is shattered/faceted.

-

Scenario 2 (Hybrid): Load Code-Cleaned

04_Outside_cleaner_Computed.vtp→ Manually applyGenerate Surface Normalsin ParaView.- Result: Point count remains high (~15k). The mesh is still shattered.

-

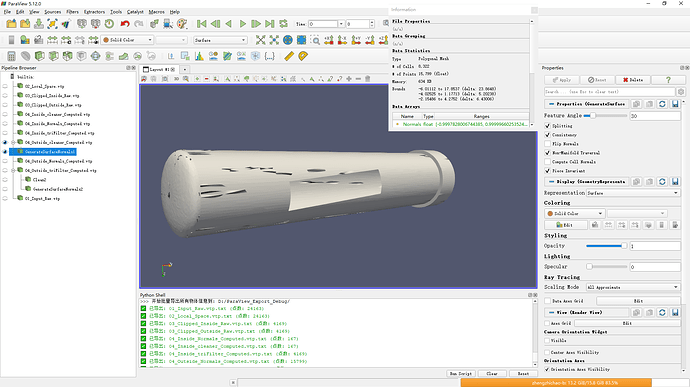

Scenario 3 (Pure ParaView Pipeline): Load Triangulated data → ParaView Manual

Clean→ ParaView ManualGenerate Surface Normals.- Result: Point count stays low (~5k). The mesh is SMOOTH. The cylinder wall is smooth, and only the cut edges are sharp.

My Conclusion & Questions

Since Scenario 3 (Pure ParaView) succeeds while Scenario 1 (Pure Code) fails—despite the intermediate “Clean” data being identical—I suspect the issue lies in the vtkPolyDataNormals configuration, specifically the Feature Angle or Splitting logic.

In my C++ code, I set the Feature Angle to 30.0 degrees.

-

Feature Angle Sensitivity: Is 30.0 degrees generally too low for a standard tessellated cylinder? Does this cause

SplittingOn()to incorrectly identify the angle between smooth curved faces as “sharp edges,” effectively re-splitting the vertices I just merged? -

ParaView Defaults: Does ParaView’s “Generate Surface Normals” filter use a default Feature Angle of 60.0? Or does it apply some extra logic to prevent over-splitting?

Here is my C++ implementation:

C++

// 1. Clean (Verified to work via export)

auto cleaner = vtkSmartPointer<vtkCleanPolyData>::New();

cleaner->SetInputData(triFilter->GetOutput());

cleaner->PointMergingOn();

cleaner->SetPieceInvariant(true);

// I used absolute tolerance to handle floating point noise from vtkBoxClipDataSet

cleaner->SetToleranceIsAbsolute(true);

cleaner->SetAbsoluteTolerance(0.001); // 1e-3

cleaner->Update();

// 2. Normals (Suspected Culprit)

auto normalGen = vtkSmartPointer<vtkPolyDataNormals>::New();

normalGen->SetInputData(cleaner->GetOutput());

normalGen->ComputePointNormalsOn();

normalGen->SplittingOn(); // I suspect this is re-splitting my welded vertices

normalGen->SetNonManifoldTraversal(true);

normalGen->ConsistencyOn();

// I used 30.0 degrees. Is this the cause?

normalGen->SetFeatureAngle(30.0);

if (isClosedMesh && IsWatertight(mesh)) {

normalGen->AutoOrientNormalsOn();

} else {

normalGen->AutoOrientNormalsOff();

}

normalGen->Update();

Step-by-Step Verification via Exported Files

I exported the model as a .vtp file after every processing step to compare the results.

04_Outside_cleaner_Computed.vtp: This is the model generated by the C++ code after passing throughvtkTriangleFilterandvtkCleanPolyData.04_Outside_triFilter_Computed.vtp: This is the model generated by the C++ code aftervtkTriangleFilter(before cleaning). I loaded this file into ParaView and manually applied the Clean filter.

- Observation: Both of the above have the exact same number of points and cells. This confirms the C++ Clean step is working identically to ParaView’s Clean step regarding topology.

However, the divergence happens at the Normals step:

04_Outside_Normals_Computed.vtp: This is the final output from the full C++ pipeline (Triangulate → Clean → Normals).GenerateSurfaceNormals1(in ParaView): I loaded the code-cleaned file (04_Outside_cleaner_Computed.vtp) and manually applied “Generate Surface Normals” in ParaView.

- Observation: This object has the same high point count as the C++ output (

04_Outside_Normals_Computed.vtp).

GenerateSurfaceNormals2(in ParaView): I loaded the raw triangulated file (04_Outside_triFilter_Computed.vtp), then manually applied the Clean filter followed by the Generate Surface Normals filter entirely within ParaView.

- Observation: This object has significantly fewer points than the previous two cases.

Any advice on why the C++vtkPolyDataNormalssplits the edges while ParaView keeps them connected would be greatly appreciated.